In today’s fast-paced architectural and interior design world, innovation isn’t just about aesthetics it’s about precision, efficiency, and sustainability. As clients demand smarter, more customized spaces, millwork drafting services have become the backbone of modern interior design and construction. From boutique hotels and corporate offices to luxury residences, millwork drafting ensures every inch of space is functional, beautiful, and flawlessly executed.

But what’s driving the surge in millwork drafting adoption, and how are these services shaping the future of custom interiors in 2025 and beyond? Let’s explore.

What Makes Millwork Drafting Essential for Modern Interior Design?

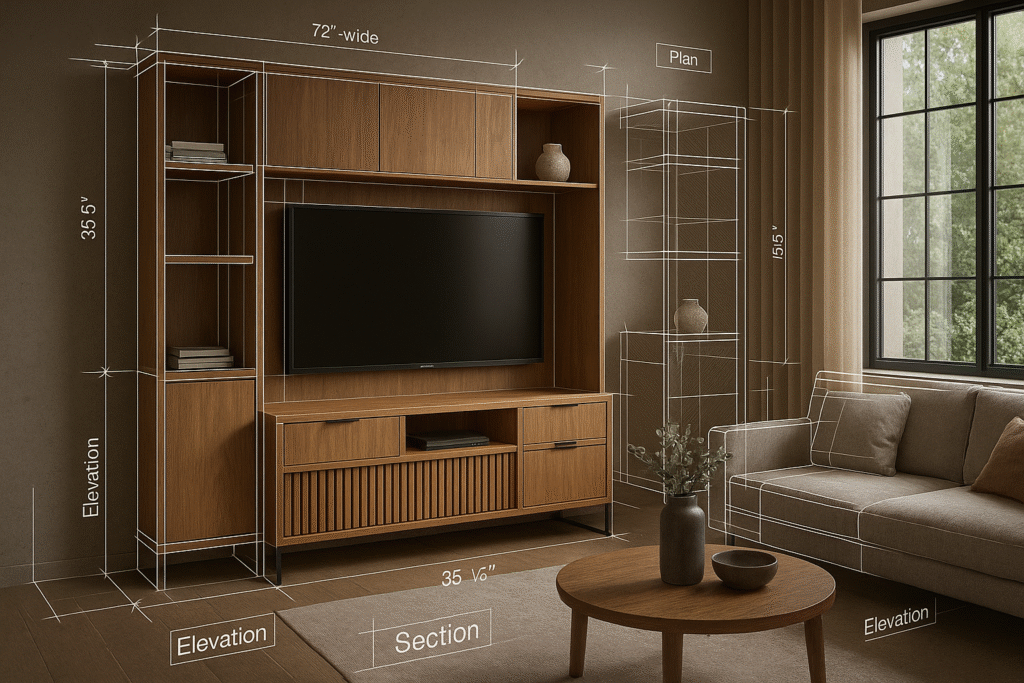

Traditional design processes often relied on manual drawings, which left room for interpretation and costly errors. Millwork drafting services eliminate that uncertainty by translating creative design ideas into precise technical drawings and detailed Millwork CAD Drawings.

This digital precision helps manufacturers, contractors, and architects collaborate seamlessly from concept to installation. The result? Consistent quality, reduced rework, and optimized production timelines.

In short: Millwork drafting acts as the bridge between imagination and execution — ensuring design intent becomes a tangible, error-free reality.

How Are Millwork Drafting Services Powering the Future of Custom Interiors?

The demand for personalized interiors is skyrocketing. According to Statista, the global interior design market is expected to reach over $255 billion by 2027, driven by technological integration and sustainable materials. Within that growth, millwork drafting services providers play a pivotal role.

Here’s how they’re shaping smarter interior design:

1. Smarter Collaboration Through Digital Integration

Modern millwork drafting relies on AutoCAD, Revit, and SolidWorks, enabling collaborative workflows between designers, fabricators, and contractors.

-

Cloud-based tools allow real-time updates and design revisions.

-

Digital models ensure uniform standards across teams and suppliers.

-

Integrated file formats minimize design-to-production delays.

By using intelligent CAD systems, teams avoid the bottlenecks that once plagued traditional projects, ensuring faster project turnaround and reduced human error.

2. Data-Driven Design Decisions

With the help of advanced Millwork CAD Drawings, designers can now test materials, finishes, and dimensions before manufacturing even begins.

For example:

-

3D visualizations allow clients to visualize custom cabinetry, furniture, or wall panels in their exact settings.

-

Simulation tools calculate spatial ergonomics and fit accuracy.

-

Predictive modeling reduces material waste and costs.

This data-driven approach aligns with the industry’s growing shift toward evidence-based design, where decisions are backed by measurable insights rather than intuition alone.

3. Reducing Costs and Errors Through Precision Drafting

One of the biggest advantages of partnering with a millwork drafting services company is cost efficiency.

According to a ResearchGate study, detailed digital documentation can reduce fabrication errors by up to 35%.

Here’s how precision drafting achieves that:

-

Error minimization: Exact measurements ensure components fit perfectly during installation.

-

Optimized material use: Accurate cut lists minimize waste.

-

Reduced rework: Fewer on-site corrections mean lower labor costs.

In an industry where one misaligned millimeter can delay a project by days, precision isn’t optional it’s essential.

4. Sustainability and Eco-Friendly Design Practices

Sustainability has become a non-negotiable factor in design. Millwork drafting services support eco-friendly practices by promoting resource optimization:

-

Drafting software calculates exact material quantities, preventing over-ordering.

-

Modular millwork designs enable easy replacement and recycling.

-

Energy-efficient layouts reduce waste across the production cycle.

With the UK and EU implementing stricter environmental standards, millwork drafting is becoming the cornerstone of green interior design balancing creativity with responsibility.

What Role Does Technology Play in the Evolution of Millwork Drafting?

The integration of AI, automation, and cloud collaboration is revolutionizing how millwork drafting companies operate. As we move toward 2025, several innovations are defining the next era of interior design production:

1. Artificial Intelligence (AI) for Design Optimization

AI-driven CAD tools can analyze past design data to recommend better configurations, materials, and construction methods. For instance:

-

Predicting weak structural areas before fabrication.

-

Suggesting cost-effective design alternatives.

-

Detecting inconsistencies in complex millwork assemblies.

This smart assistance not only enhances accuracy but also accelerates the design approval process.

2. BIM (Building Information Modeling) Integration

Building Information Modeling (BIM) has become a gold standard for architectural collaboration. By integrating millwork drafting into BIM environments like Revit, teams can ensure seamless alignment between architectural, structural, and MEP components.

This means fewer conflicts, better documentation, and enhanced visualization particularly important for bespoke interiors where every element must fit within a larger architectural narrative.

3. Cloud-Based Collaboration Tools

Remote collaboration has reshaped how CAD design companies work globally. Cloud-based platforms such as Autodesk Construction Cloud and Trimble Connect allow stakeholders to:

-

Access and edit drawings from anywhere.

-

Track real-time updates.

-

Maintain version control across multiple drafts.

For UK and US-based architecture firms handling global projects, this remote flexibility ensures continuity and quality control at every stage.

What Are the Key Challenges in Millwork Drafting and How Can Companies Overcome Them?

While technology is empowering, it also presents new challenges that designers and drafters must navigate:

-

Skill Gaps: Rapid software evolution requires constant upskilling in AutoCAD, Revit, and 3D modeling tools.

-

Data Security: With cloud-based collaboration comes the need for stronger cybersecurity measures.

-

Interdisciplinary Coordination: Designers, engineers, and manufacturers must align data formats and design standards to avoid integration issues.

Leading millwork drafting services providers are addressing these challenges through:

-

Continuous training programs.

-

Secure cloud infrastructures.

-

Standardized workflows and documentation protocols.

By building multidisciplinary teams and leveraging automation, these companies deliver projects faster, more accurately, and more sustainably than ever before.

Why Is the Demand for Millwork Drafting Growing in the UK and Globally?

The UK interior design industry has experienced consistent growth, driven by corporate renovations and luxury home makeovers. According to IBISWorld, the UK interior design sector generates over £2 billion annually, and the demand for customized millwork elements continues to rise.

Businesses across hospitality, retail, and residential sectors now view millwork drafting as a strategic advantage rather than a technical necessity. The reason is simple it enables bespoke craftsmanship, reduces lead time, and ensures flawless on-site execution.

How Millwork Drafting is Redefining the Designer Manufacturer Relationship

Gone are the days when designers handed over rough sketches to fabricators. Today, millwork drafting services create a shared digital language between the creative and technical sides of design.

-

Designers can visualize aesthetic intent through detailed renderings.

-

Manufacturers can extract precise fabrication data directly from drawings.

-

Installers benefit from assembly-ready instructions and component labeling.

This alignment not only minimizes misunderstandings but also strengthens collaboration throughout the project lifecycle ensuring that what’s imagined is exactly what’s built.

The Road Ahead: What’s Next for Millwork Drafting Services?

The next wave of millwork innovation will combine AI-driven generative design, IoT-enabled smart furniture, and AR-based visualization tools. Imagine clients walking through a virtual interior before fabrication begins making real-time adjustments to finishes, proportions, and lighting.

As these technologies mature, millwork drafting services companies that invest in innovation and sustainability will lead the market, offering clients smarter, faster, and more precise design-to-build experiences.

Conclusion:

The future of custom interiors is intelligent, data-driven, and deeply collaborative. As businesses seek designs that balance aesthetics, performance, and sustainability, millwork drafting services will remain a vital part of that transformation.

By combining digital precision with creative craftsmanship, these services empower architects, designers, and manufacturers to deliver smarter, cost-efficient, and future-ready interiors.

If you’re looking to bring your design visions to life with accuracy and innovation, partnering with a leading UK CAD design company can help you stay ahead in the evolving world of millwork and interior design.