Introduction

Recycled Polyethylene Terephthalate (RPET) packaging represents a transformative solution in the global drive toward sustainability, waste reduction, and circular economy practices. RPET is derived from post-consumer PET plastics, predominantly beverage bottles, that undergo a rigorous recycling process to produce high-grade packaging materials. These materials retain the key physical characteristics of virgin PET, including clarity, strength, and durability, while offering significant environmental advantages.

The use of RPET in packaging has emerged as a cornerstone of eco-conscious branding and operations across industries, particularly in food and beverages, personal care, household products, and pharmaceuticals. The increasing regulatory pressure to reduce plastic waste, coupled with heightened consumer awareness, has accelerated the demand for RPET-based solutions that minimize environmental footprint without compromising performance or aesthetics.

As governments, manufacturers, and consumers align toward more sustainable materials, RPET packaging has transitioned from a niche option to a mainstream packaging solution with global relevance. Its role is central to achieving sustainability targets and reducing dependency on virgin fossil-based plastics.

Source: https://www.databridgemarketresearch.com/reports/global-recycled-polyethylene-terephthalate-market

The Evolution

The adoption of RPET packaging can be traced back to growing environmental concerns around the late 20th century, especially regarding the mounting accumulation of plastic waste in landfills and oceans. Initially, the recycling of PET was limited and lacked industrial-scale infrastructure. Early RPET products were often limited in application and quality due to challenges in sorting, contamination, and inadequate technology.

By the early 2000s, advances in recycling technologies, particularly mechanical and chemical recycling, allowed the production of food-grade RPET. This development was a game-changer, enabling RPET to be used in high-volume and high-regulation sectors. Innovations in closed-loop recycling systems allowed used PET bottles to be collected, cleaned, processed, and transformed back into packaging material of equivalent quality.

Regulatory initiatives across North America, Europe, and Asia pushed industries to integrate higher recycled content in packaging. Brand owners began incorporating recycled content into packaging as part of broader environmental, social, and governance (ESG) commitments. The development of enhanced sorting technologies using infrared sensors and AI-driven material recovery facilities significantly improved the quality and yield of RPET production.

Today, RPET is a preferred material for numerous global packaging formats, including bottles, clamshell containers, thermoformed trays, films, and pouches. The evolution from basic recycling to a highly efficient closed-loop ecosystem has redefined RPET as both an environmental and economic solution in the packaging landscape.

Market Trends

Widespread incorporation of RPET in primary and secondary packaging across consumer goods

Growing retail and e-commerce adoption of transparent and lightweight RPET containers

Shift toward monomaterial packaging designs to improve recyclability

Government mandates for minimum recycled content in packaging across major economies

Rise in eco-labeling and certifications promoting packaging sustainability

Increased brand investment in circular economy infrastructure for PET recovery

Popularity of clear, food-grade RPET bottles in beverages and dairy sectors

Development of RPET thermoformed packaging for ready meals and bakery items

Utilization of RPET films and wraps in fresh produce and frozen food packaging

Adoption of advanced decontamination technologies to produce high-purity RPET

Surge in demand for RPET from the cosmetics and personal care industry

Innovations in lightweighting and downgauging RPET containers for material efficiency

Emergence of ocean-bound RPET as a premium sustainable packaging option

Use of chemical recycling and depolymerization for higher RPET yield

Integration of digital tracing technologies in the RPET supply chain

Challenges

Inconsistency in supply and quality of post-consumer PET waste

High costs of food-grade RPET compared to virgin PET

Limited availability of recycling infrastructure in developing regions

Color and clarity variability affecting aesthetic quality in premium packaging

Mechanical degradation of PET over multiple recycling cycles

Contamination from non-PET materials during collection and sorting

Complexity in meeting food safety and pharmaceutical-grade standards

Restricted market access due to differing regulatory frameworks worldwide

Technical difficulties in achieving uniform material properties across batches

Competition with other recycled polymers such as recycled HDPE and recycled PP

Consumer misperceptions regarding the safety or quality of recycled plastics

Insufficient incentives for local governments to improve collection rates

Environmental footprint of long-distance transportation of recycled materials

Limited investment in chemical recycling due to high capital requirements

Difficulty in creating closed-loop systems for multilayer or composite packaging

Market Scope

By Product Type

Bottles

Clamshells and Containers

Films and Sheets

Trays and Punnets

Pouches

Straps

Others (Caps, Lids, etc.)

By Grade

Clear RPET

Colored RPET

Food-Grade RPET

Non-Food-Grade RPET

By Processing Technology

Mechanical Recycling

Chemical Recycling

Hybrid Technologies

By Application

Food and Beverage Packaging

Personal Care and Cosmetics Packaging

Pharmaceutical Packaging

Household Products Packaging

Industrial Packaging

Textile and Apparel Packaging

By End Use Industry

FMCG

Retail and E-commerce

Pharmaceutical and Healthcare

Hospitality

Agriculture and Horticulture

Electronics and Industrial Goods

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

The RPET packaging market serves a wide array of sectors, with food and beverages leading in terms of volume due to stringent safety regulations and high consumer turnover. Personal care, pharmaceuticals, and e-commerce are fast-growing segments adopting RPET for sustainable branding and logistics.

Market Size

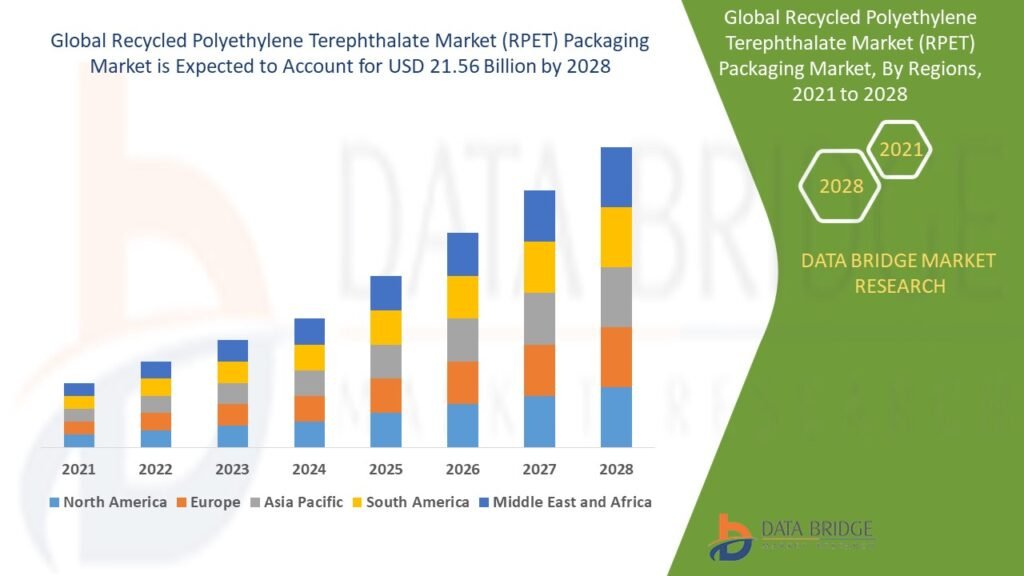

The global RPET packaging market was valued at approximately USD 11.8 billion in 2024 and is projected to reach USD 23.6 billion by 2030, growing at a CAGR of 12.1% over the forecast period. Growth is driven by increased recycled content mandates, corporate sustainability goals, and the evolution of advanced recycling technologies.

North America and Europe dominate the current market due to robust recycling systems, high consumer awareness, and regulatory enforcement. Asia-Pacific is emerging rapidly due to growing consumer markets, government-led sustainability initiatives, and expanding industrial recycling capacities.

The food and beverage sector remains the largest user of RPET packaging, accounting for over 50% of market share. Bottles, containers, and trays are the most common packaging formats, followed by films and wraps. Demand for transparent, high-clarity RPET materials continues to rise due to their appeal in shelf display and branding.

Factors Driving Growth

Rising demand for sustainable packaging solutions across consumer industries

Regulatory requirements for recycled content in packaging by regional authorities

Corporate ESG targets encouraging adoption of recycled materials

Technological improvements in mechanical and chemical recycling efficiency

Public awareness campaigns about plastic pollution and circular economy benefits

Cost-effective packaging production using recycled content in high volumes

Increased demand for lightweight, clear, and durable packaging materials

Availability of RPET with comparable mechanical properties to virgin PET

Brand differentiation through the use of eco-labeled packaging

Expanding PET bottle collection programs in urban and rural regions

Advancements in PET flake washing, drying, and extrusion technologies

Growth in e-commerce driving demand for protective and sustainable packaging

Packaging innovation using RPET blends and barrier coatings for extended shelf life

Partnerships among governments, NGOs, and brands to improve PET recovery rates

Consumer preference for environmentally responsible packaging formats

Emergence of refillable packaging models compatible with RPET designs

Recycling-friendly packaging designs reducing multilayer and mixed material usage

Greater traceability and certification of post-consumer recycled content

Scaling of closed-loop packaging systems by multinational brands

Conclusion

The recycled polyethylene terephthalate (RPET) packaging market has emerged as a critical enabler of sustainable development within the global packaging industry. Its evolution from basic post-consumer recycling to advanced, high-purity applications in food-grade and pharmaceutical packaging reflects the growing alignment of market forces with environmental stewardship.

RPET packaging not only addresses the pressing issue of plastic pollution but also delivers practical benefits in terms of cost, functionality, and branding. Its role in helping industries reduce their carbon footprint, meet regulatory requirements, and respond to consumer demands is set to expand exponentially in the coming years.

While challenges in supply chain logistics, quality control, and regulatory harmonization remain, the continued investments in recycling infrastructure, technological innovation, and consumer education are expected to overcome these hurdles. RPET is now a pillar of the circular economy and an indispensable material in the journey toward a more sustainable packaging future.