From the stairwell of a factory to the ramp at the entrance to a public building, these locations need to be slip-resistant and secure. Grating, especially non-slip grating types such as anti-slip GRP grating, anti-slip floor grating, and anti-slip metal grating, offer a permanent and sound solution to the mitigation of hazards and improved safety.

Learning About Grating and Its Function

Grating provides drainage, ventilation, and traction and is therefore suited for applications where there can be potential moisture, oils, and other slip-inducing liquids.

Where there is high usage or risk surrounding it, normal grating may not be sufficient to provide protection. Anti-slip grating is thus on the increase. It is tailored with gritted surfaces or grit-embedded sheets to enhance footing even when dirty or wet.

The Importance of Anti-Slip Features

Safety is given prominence while staircases and ramps are being constructed, particularly in areas where individuals are on the move or on foot with loads. Anti-slip grating is designed to avoid slip accidents by providing added friction between the surface and feet. The advantage of the added traction is most pronounced in areas that are exposed to:

- Rain or moisture

- Chemical spills

- Oil and grease

- Snow or ice

Highly Populated Pedestrian or Vehicle Traffic

Without adequate anti-slip measures, stairways and ramps are hazard zones. Non-slip grating installation will go a long way in curtailing accidents and compliance with safety and health legislation.

Types of Anti-Slip Grating for Safety Purposes:

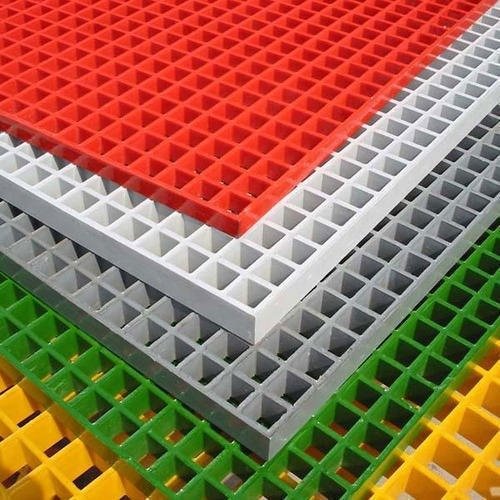

There are various categories of anti-slip grating, each with an application for use in its respective environment. Some of the most used types are outlined below:

Anti-Slip GRP Grating:

Anti-slip GRP grating is a light, corrosion-free metal substitute. It is resin and fiberglass construction, especially for harsh applications like chemical plants, marine atmospheres, and food preparation areas. GRP gratings have quartz grit surfaces, which are highly slip resistant.

Benefits:

- Non-corrosive

- Lightweight to install

- Fire retardant

- Superior enduring slip resistance

- Electrically non-conductive

Anti-Slip Metal Grating:

Metal Grating, steel or aluminum, is one of the most common industrial selections because of its strength and durability. Anti-slip metal grating has serrated surfaces or tread plates incorporated for better grip.

Advantages:

- Superior load-bearing capacity

- Long-term withstanding exposure to tough conditions

- Ideal for heavy machinery traffic and pedestrian traffic

- Galvanized commonly to avoid rusting

Anti-Slip Floor Grating:

It is a name mainly describing any grating permanently installed in walkways or platforms with anti-slip characteristics. Anti-slip floor grating is generally found installed in warehouses, rooftops, maintenance platforms, and manufacturing facilities.

Most distinguishing features:

- May be produced to fit any floor plan.

- Offers drainage as well as debris passage.

- Plastic, metal, and GRP material availability

Plastic Grating:

Plastic grating, which is normally manufactured from high-density polyethylene (HDPE) or polypropylene, is corrosion-resistant and suitable for applications where sanitary floor covering is needed, like food factories or swimming pools.

Not as wear-resistant as metal or GRP, plastic grating remains useful in anti-slip applications with grit surfaces or molded-in finishes.

Advantages:

- Corrosion-resistant

- Lightweight

- Non-conductive

Easy to clean:

Advantages of Using Anti-Slip Grating on Ramps and Staircases

Enhanced Safety and Compliance:

The main advantage is increased safety. Anti-slip grating prevents falls in a substantial way, safeguarding workers, visitors, and members of the public. It also enables companies to comply with safety requirements and stay out of legal strife.

Durability and Low Maintenance:

Regardless of whether it is GRP, metal, or plastic grating, all the materials are resistant to wear and thus can be a permanent installation. They need less maintenance than other surfaces such as wood or plain concrete.

Effective Drainage:

The grid pattern of the grating permits water, oil, and other liquids to drain freely without puddles and slippery surfaces, which contribute to slips.

Versatility in Design:

Anti-slip gratings are applicable in a vast range of environments—from warehouses and factories to outside ramps and walkways. Anti-slip gratings can be profiled and sized to order and completely fill areas of risk.

Easy Installation:

Grating systems are often installed quickly and simply by clips, bolts, or module fittings. This saves time and labor. Read This

Choosing the Correct Grating for Your Application:

Environment: Chemical, weather, or water exposure

Traffic Type: Vehicle vs. pedestrian

Load Requirements: Larger loads need tougher material, such as metal.

Maintenance Needs: Opt for material that is simple to clean and will not be impaired by buildup.

Cost vs. Longevity: GRP could be more expensive in the short term but has long-term cost benefits with its degree of durability.