Introduction

The global hydraulics market—valued at $45.8 billion in 2024 and projected to reach $66.3 billion by 2030 (CAGR 6.1%)—remains the backbone of industrial automation, construction, and aerospace. From colossal excavators to micro-scale surgical robots, hydraulic systems convert fluid power into mechanical force with unmatched efficiency. As industries demand smarter, greener, and more resilient machinery, hydraulic technology is undergoing a radical transformation. This post explores its evolution, current disruptions, and the high-pressure opportunities ahead.

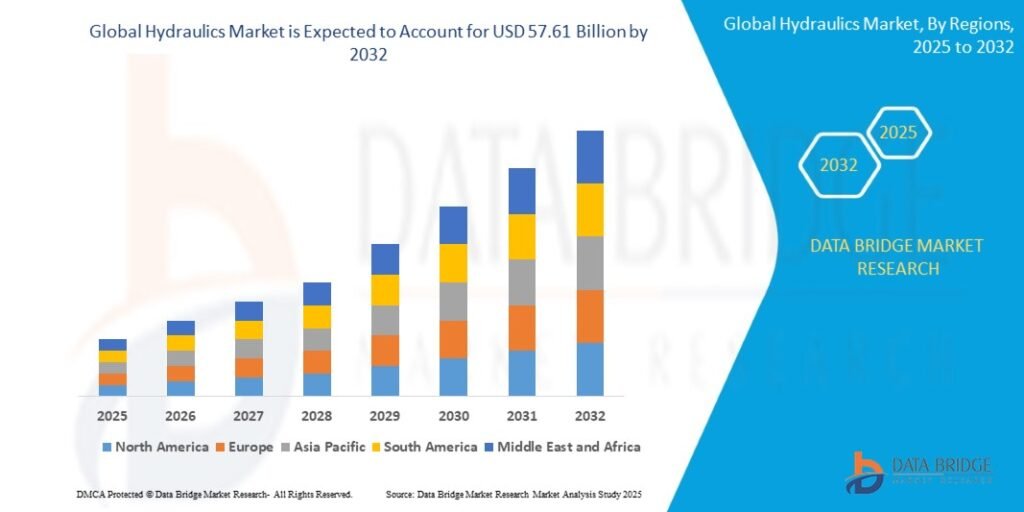

Source: https://www.databridgemarketresearch.com/reports/global-hydraulics-market

The Evolution of Hydraulic Systems

1. Mechanical Foundations (1800s–1940s)

-

Pascal’s Principles: Early applications in presses and lifts.

-

Industrial Revolution: Steam-powered hydraulics for factories and ships.

2. Post-War Boom (1950s–1990s)

-

Mobile Hydraulics: Excavators, cranes, and agricultural machinery drove demand.

-

Aerospace Leap: Hydraulic flight controls enabled commercial aviation growth.

3. Digital Age (2000s–Present)

-

Electro-Hydraulic Synergy: Sensors and software enabled precision control.

-

Miniaturization: Micro-hydraulics for medical devices and robotics.

-

Sustainability Shift: Bio-degradable fluids and energy-recovery systems.

Current Market Trends

1. Electrification & Hybrid Systems

-

Electric Actuators: Replacing traditional pumps in factories (20% energy savings).

-

Hybrid Construction Gear: Diesel-hydraulic-electric excavators cut emissions by 30%.

2. Smart Hydraulics

-

IoT Sensors: Real-time pressure/temperature monitoring to predict failures.

-

Digital Twins: Simulating hydraulic system performance for predictive maintenance.

3. Sustainable Fluids & Design

-

Bio-Based HLP Fluids: Soybean and rapeseed oils replacing petroleum.

-

Closed-Loop Systems: Recycling fluid to reduce waste by 90%.

4. Compact, High-Power Solutions

-

High-Pressure Pumps (500+ bar): Enabling lighter aerospace and EV components.

-

Additive Manufacturing: 3D-printed hydraulic manifolds cutting weight by 40%.

Key Challenges

-

Environmental Regulations

-

Fluid Disposal Costs: Strict EPA/EU rules on synthetic fluid recycling.

-

CO2 Targets: Pressure to reduce energy consumption in hydraulic systems.

-

-

Supply Chain Vulnerabilities

-

Rare Earth Dependencies: Chinese control over 80% of magnet production (critical for pumps).

-

Steel Price Volatility: 34% cost surge post-pandemic.

-

-

Skills Gap

-

Shortage of engineers trained in digital hydraulics and mechatronics.

-

-

Competition from Electrics

-

Linear motors threatening hydraulic cylinders in automation.

-

Market Scope & Segmentation

By Component

| Segment | Growth Driver |

|---|---|

| Pumps & Motors | Electrification of construction fleets |

| Valves | Smart factories requiring precision |

| Cylinders | Wind turbine installation boom |

| Fluids | Shift to bio-based solutions |

By End-Use

-

Construction (35% market share): Urbanization in Asia-Pacific.

-

Aerospace (18%): Next-gen aircraft requiring lightweight hydraulics.

-

Agriculture (15%): Automation in precision farming.

-

Healthcare (5%): Surgical robots and MRI table systems.

By Region

-

Asia-Pacific (45% revenue): China’s infrastructure push.

-

North America (30%): Shale gas and aerospace R&D.

-

Europe (20%): Sustainability mandates driving green hydraulics.

Market Size & Growth Drivers

-

2024 Value: $45.8B → 2030 Projection: $66.3B (CAGR 6.1%).

6 Catalysts Accelerating Growth:

-

Infrastructure Mega-Projects: $3.2T U.S. bill; India’s $1.3T Gati Shakti.

-

Renewable Energy Expansion: Hydraulic pitch/yaw systems in 90% of wind turbines.

-

Automation Surge: Hydraulic robots in automotive assembly (precision > pneumatics).

-

Aging Aircraft Fleets: 40% of global planes requiring hydraulic retrofits by 2030.

-

Water Scarcity Solutions: Smart hydraulic valves in drip irrigation.

-

Defense Modernization: Electrodynamic actuators in military vehicles.

Conclusion: The Fluid Future

The hydraulics market is not merely evolving—it’s reinventing power transmission. Winners will prioritize:

-

Circular Design: Recyclable components and closed-loop fluid systems.

-

Digital Integration: AI-driven efficiency and remote diagnostics.

-

Material Science: Graphene-enhanced seals and self-healing hoses.

For manufacturers, investing in electro-hydraulic convergence and talent development is critical. For end-users? A future where hydraulic systems are whisper-quiet, energy-positive, and seamlessly connected—proving that this 200-year-old technology still holds the high ground in industrial innovation.