Polyvinyl alcohol (PVA) filament is rapidly gaining popularity in the 3D printing community, thanks to its unique properties and versatility. As 3D printing technology continues to advance, the demand for innovative materials that can enhance the functionality and sustainability of printed objects has grown. PVA filament, a water-soluble polymer, has emerged as one of the most important materials for additive manufacturing. It is particularly useful in applications that require high-quality support structures, environmentally friendly solutions, and advanced material properties. polyvinyl alcohol filament

What is Polyvinyl Alcohol (PVA)?

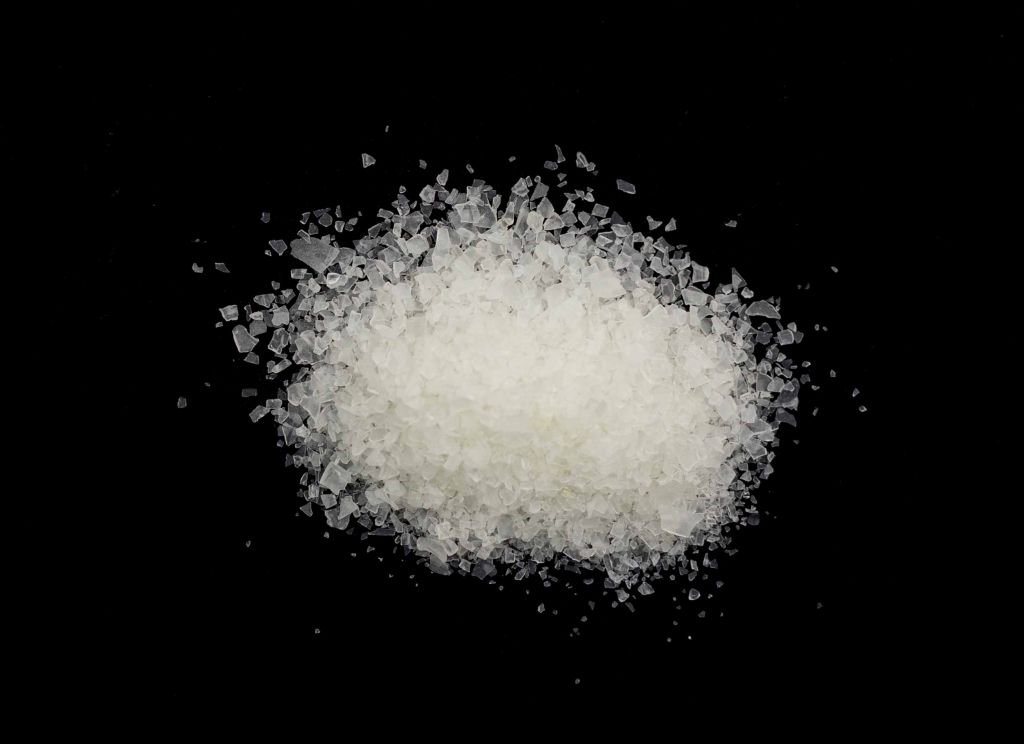

Polyvinyl alcohol is a synthetic polymer made by polymerizing vinyl acetate and then hydrolyzing the resulting polyvinyl acetate (PVA) into polyvinyl alcohol. This process replaces ester groups with hydroxyl groups, creating a water-soluble material with excellent film-forming capabilities. PVA is known for its biodegradability, low toxicity, and ability to dissolve completely in water, making it an ideal choice for various industries, including 3D printing.

In the context of 3D printing, PVA filament is often used as a support material for complex geometries. Unlike traditional support materials such as PLA or ABS, PVA can be dissolved in water after the printing process, making it a highly effective solution for supporting intricate designs without leaving any residue or marks.

Key Properties of PVA Filament

- Water-Solubility:

The most notable feature of PVA filament is its solubility in water. This characteristic allows for easy removal of support structures from a 3D print without the need for mechanical extraction. After printing, the object is submerged in warm water, and the PVA support material dissolves completely, leaving behind only the final printed object. - Biodegradability:

PVA is biodegradable, which makes it an environmentally friendly material. Unlike traditional plastic filaments that can take hundreds of years to break down, PVA breaks down relatively quickly when exposed to water or other environmental factors. This feature makes PVA filament an attractive choice for sustainable 3D printing. - High Adhesion to Various Materials:

PVA filament has excellent adhesion properties, particularly with other materials commonly used in 3D printing, such as PLA, ABS, and PETG. It bonds well with these filaments, ensuring that the printed object is securely supported during the printing process. - Transparency:

PVA filament is typically available in a clear or semi-transparent form, which allows for visually appealing prints, especially in applications where the support material might need to be inspected during the printing process. The transparency also makes it easier to monitor the dissolution of the support material in water. - Low Toxicity:

PVA filament is non-toxic and does not release harmful fumes during the printing process, making it safe for use in enclosed spaces without requiring extensive ventilation. This makes PVA an ideal material for home users and educational environments.

Common Applications of PVA Filament

- Support Structures in Complex Prints:

One of the most common uses of PVA filament in 3D printing is for creating support structures. When printing objects with overhangs, bridges, or intricate designs, PVA can be used to generate scaffolding that supports these features during the printing process. Once the print is complete, the PVA supports can be dissolved in water, leaving behind a clean, finished object without the need for manual support removal or post-processing. - Multi-Material 3D Printing:

PVA is frequently used in conjunction with other filaments in multi-material 3D printing. This technique involves printing a primary material, such as PLA or ABS, along with PVA as a support material. Since PVA dissolves in water and does not interfere with the main material, it allows for the creation of highly detailed and complex parts that would be impossible to print with a single material. - Prototyping and Engineering:

PVA filament is also used in prototyping applications where quick iteration and complex geometries are required. Engineers and designers often use PVA supports to test and validate prototypes before moving to final production. The ability to dissolve support structures easily reduces the time and labor involved in post-processing. - Artistic and Creative Projects:

The transparency of PVA filament allows artists to create unique effects in their 3D prints. The ability to print complex, delicate, and intricate designs, combined with the dissolvable support material, allows for creative freedom in producing sculptures, jewelry, and other artistic objects. - Medical Applications:

In the medical field, PVA filament has found use in the creation of custom prosthetics and surgical tools. The ability to dissolve supports in water makes PVA an ideal material for creating complex, patient-specific designs that require intricate internal channels or overhangs.

Advantages of Using PVA Filament

- Ease of Use: PVA filament is easy to print with, especially when used in dual-extruder 3D printers. The water-soluble nature of PVA simplifies post-processing, reducing the need for labor-intensive support removal.

- Environmental Benefits: As a biodegradable and water-soluble material, PVA is a more sustainable alternative to petroleum-based filaments like ABS and PLA, which do not dissolve and can persist in landfills.

- No Residue Left Behind: Unlike traditional support materials, which may leave residue or require sanding, PVA dissolves completely in water, ensuring a clean, smooth final product.

- Safer for Home Use: PVA filament does not emit harmful fumes or particles during the printing process, making it safer for home environments and spaces with limited ventilation.

Challenges and Limitations of PVA Filament

While PVA filament has many advantages, it is not without its limitations. One of the challenges of using PVA is its sensitivity to moisture. PVA filament is hygroscopic, meaning it can absorb moisture from the air, which can affect its printing performance. To mitigate this, PVA filament should be stored in a dry environment, and some users opt for filament dryers or desiccant packs to prevent moisture absorption.

Additionally, PVA filament can be more expensive than other filaments like PLA or ABS. This cost factor may limit its use in certain applications, particularly for large prints that require a significant amount of support material.

Conclusion

Polyvinyl alcohol (PVA) filament is an innovative material that offers numerous benefits for 3D printing, especially in applications requiring complex geometries and multi-material printing. Its water-solubility, biodegradability, and ease of use make it a valuable tool for both hobbyists and professionals. While it does come with certain challenges, such as moisture sensitivity and cost, the advantages far outweigh the drawbacks, particularly in specialized use cases like support material and multi-material prints. As 3D printing continues to evolve, PVA filament is likely to play an even more significant role in advancing the capabilities of additive manufacturing, making it a crucial material for the future of 3D printing.