In the rapidly evolving construction industry, speed, safety, and precision are the three pillars of successful project execution. Among the various innovations transforming the construction landscape, the Slab Formwork System stands out as a key contributor to efficient concrete slab casting. Whether you are building residential apartments, commercial spaces, or large infrastructure, using the right slab formwork system can dramatically improve the quality and timeline of construction.

At Biiformtek, we offer modern, modular, and reusable slab formwork solutions engineered for strength, versatility, and ease of use. When integrated with our Slab Edge Protection System, our offerings not only enhance productivity but also ensure a safe working environment for your on-site teams.

Understanding the Slab Formwork System

A Slab Formwork System is a temporary yet critical structure designed to hold freshly poured concrete in place until it hardens and gains sufficient strength to support its own weight. Traditionally made from timber, formwork systems have now evolved into engineered modular systems made from high-strength steel, aluminum, or composite materials.

These systems are essential for shaping slabs, maintaining accurate dimensions, and ensuring flatness, while also allowing early removal and reusability in multiple projects.

Key Components of a Slab Formwork System

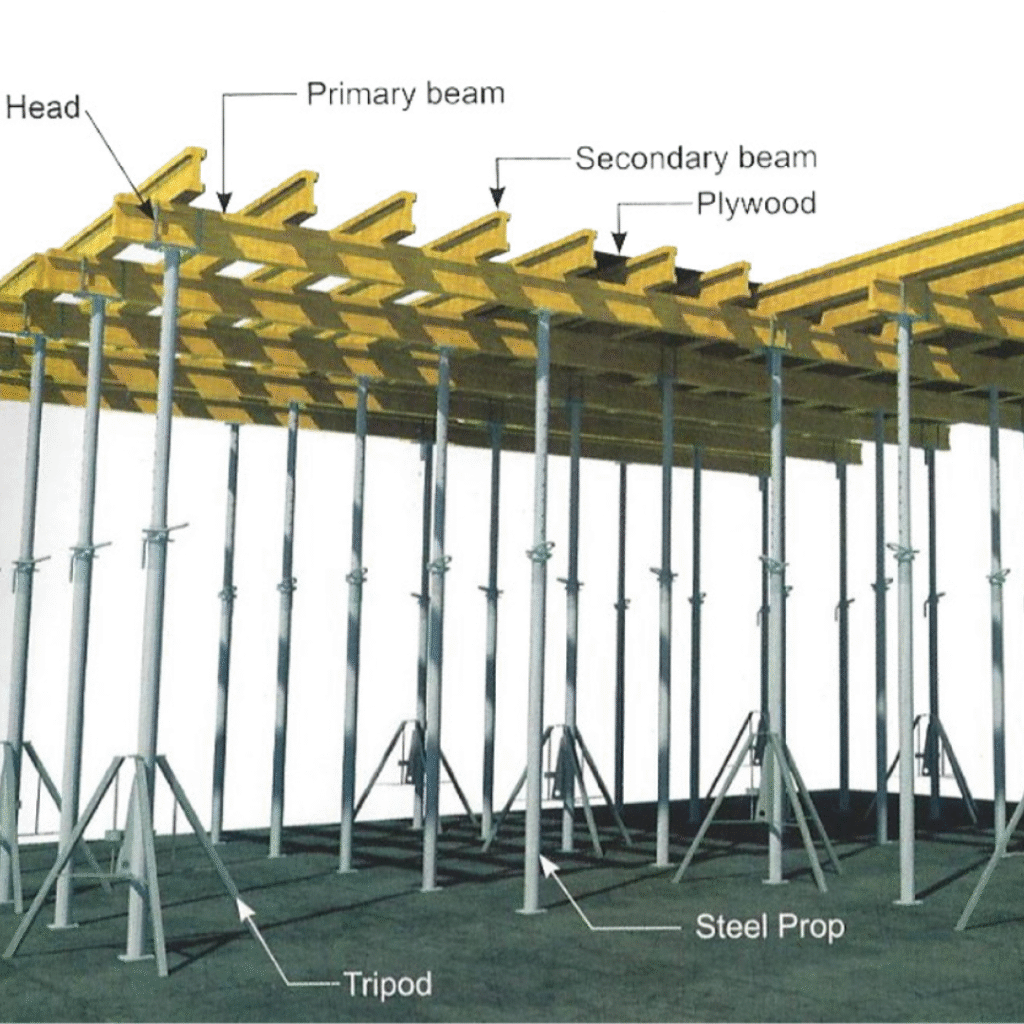

A complete and modern Slab Formwork System typically includes:

- Deck Panels: Horizontal surfaces that support the concrete pour.

- Adjustable Props: Vertical supports that bear the weight of wet concrete and formwork.

- Main and Secondary Beams: Provide structural strength and evenly distribute the load.

- Drop Heads: Enable early removal of deck panels while leaving props for continued support.

- Formwork Accessories: Includes connectors, clamps, leveling jacks, and safety pins for quick and secure installation.

These systems are modular, allowing for flexibility and rapid assembly on construction sites of all types and sizes.

Benefits of Using a Slab Formwork System

- Faster Construction Cycles

Modular design and efficient handling reduce assembly and dismantling times, speeding up project timelines significantly.

- Superior Surface Finish

Accurately designed panels result in smoother concrete surfaces, reducing the need for post-pour finishing or plastering.

- Cost-Effective and Reusable

Modern systems can be reused across multiple projects, reducing material costs and environmental impact.

- Improved Load-Bearing Capacity

The structural integrity of steel or aluminum systems allows for higher load capacity without deformation.

- Safety Integration

Designed to work seamlessly with a Slab Edge Protection System, they ensure worker safety and site compliance with regulatory standards.

Importance of Slab Edge Protection System

While the Slab Formwork System supports the structural aspect, the Slab Edge Protection System ensures site safety—particularly during high-rise and elevated slab construction. It acts as a safety barrier around open slab edges to prevent falls, accidents, and unauthorized access.

Key Elements of Slab Edge Protection:

- Guardrails or Mesh Panels – Installed along slab edges to prevent falls.

- Toe Boards – Prevent tools or small objects from falling off edges.

- Anchor Clamps – Secure the guardrails to formwork or the slab itself.

- Adjustable Posts – Allow compatibility with slabs of varying thickness.

Together, the formwork and edge protection systems create a robust framework for safer and more productive job sites.

Applications in Modern Construction

Slab Formwork Systems are used across a wide range of construction types, such as:

- Residential High-Rise Apartments

- Commercial Buildings and Offices

- Hospitals, Schools, and Malls

- Industrial Complexes

- Parking Structures and Basements

- Infrastructure and Transport Facilities

The adaptability of formwork systems allows them to accommodate flat slabs, drop beams, waffle slabs, and beam-slab combinations.

Why Choose Biiformtek’s Slab Formwork System?

At Biiformtek, our Slab Formwork Systems are designed for functionality, ease of use, and durability. We understand the complex needs of modern construction projects and offer systems that deliver high performance under varying conditions.

- Modular and Easy to Handle

Our systems are designed for quick setup and dismantling, reducing labor costs and on-site clutter.

- High Strength and Reliability

Built from high-grade steel and aluminum, our formwork components provide excellent load-bearing capacity and longevity.

- Integrated Safety Features

Our systems are fully compatible with Slab Edge Protection Systems, ensuring a safer workspace without compromising speed.

- Custom Design Support

Our engineering team provides layout planning, load calculations, and project-specific configurations to optimize site execution.

- On-Site Technical Assistance

We offer training and supervision to ensure smooth installation and correct usage, minimizing errors and delays.

Compliance and Safety Standards

Both formwork and edge protection systems must adhere to industry safety codes. At Biiformtek, we ensure compliance with:

- IS Codes for Formwork Safety and Design

- OSHA Guidelines for Fall Protection

- EN 13374 Standards for Edge Protection Systems

This guarantees our solutions meet both national and international safety standards, helping clients avoid legal or operational risks.

Sustainability and Environmental Impact

Using engineered Slab Formwork Systems reduces the need for disposable timber, significantly cutting down on construction waste. Our steel and aluminum systems are recyclable and designed for repeated use, making them eco-friendly and cost-effective.

Benefits include:

- Reduced site waste

- Lower carbon emissions

- Minimal material usage

- Long lifespan and recyclability

Trends and Innovations in Formwork Technology

The future of construction lies in automation, digital design, and data-driven execution. Slab Formwork Systems are now being integrated with:

- BIM (Building Information Modeling) for layout and clash detection

- Prefabricated Table Form Systems for large repetitive slabs

- Smart Sensors to monitor pressure, alignment, and concrete curing

- IoT-based Tracking for component usage and site logistics

Biiformtek stays ahead of the curve by adopting these technologies, offering our clients smarter, faster, and safer construction solutions.

Final Thoughts

The Slab Formwork System is more than just a support structure—it’s a foundation for successful concrete construction. When combined with a secure Slab Edge Protection System, it forms a complete ecosystem that ensures both operational efficiency and worker safety.

Whether you’re looking to reduce labor costs, improve concrete finish, accelerate your schedule, or comply with safety norms, Biiformtek has the right solution. Our robust, reusable, and modular systems are designed to support your project goals with unmatched quality and precision.

Explore our full range of products at Biiformtek and get in touch with our expert team to find the ideal slab formwork and safety solution for your next project.