Stainless steel has become the backbone of modern industries because of its strength, durability, and resistance to corrosion. Among the different stainless steel grades, SS 316 Square Bars hold a significant place due to their outstanding mechanical properties and excellent corrosion resistance. They are widely used in marine, chemical, construction, and food industries, making them a popular choice among engineers, fabricators, and manufacturers.

This blog explores everything you need to know about SS 316 square bars, including their properties, advantages, applications, and why they are a preferred material in challenging environments.

What Are SS 316 Square Bars?

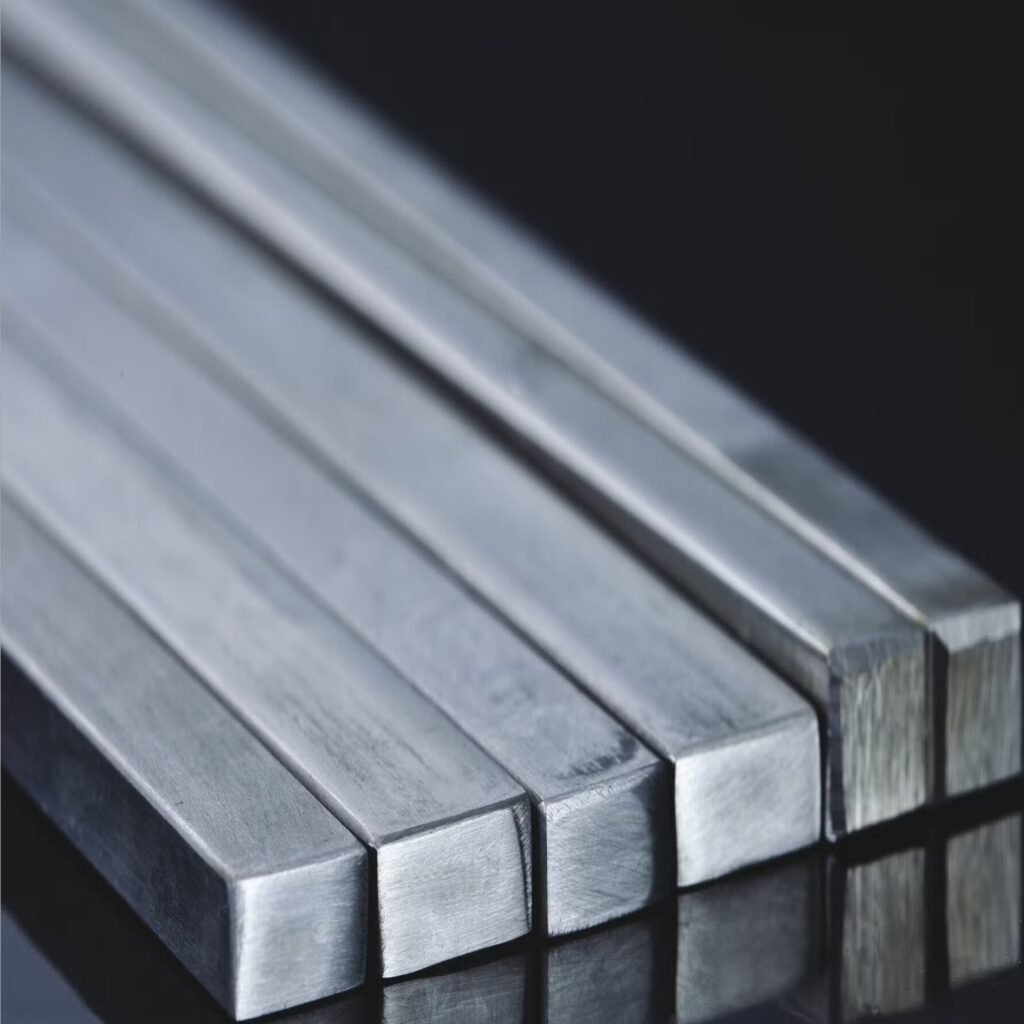

SS 316 Square Bars are stainless steel products with a square cross-section made from grade 316 stainless steel, an austenitic chromium-nickel alloy. They are known for their high strength, superior surface finish, and excellent corrosion resistance in chloride and marine environments.

The addition of molybdenum (2–3%) in grade 316 makes it more resistant to pitting and crevice corrosion compared to SS 304. This is why SS 316 is often called marine grade stainless steel. Square bars are available in various sizes and thicknesses, catering to the needs of diverse industries.

Chemical Composition of SS 316 Square Bars

The chemical makeup of SS 316 square bars defines their performance:

-

Carbon (C): 0.08% max

-

Chromium (Cr): 16.0 – 18.0%

-

Nickel (Ni): 10.0 – 14.0%

-

Molybdenum (Mo): 2.0 – 3.0%

-

Manganese (Mn): 2.0% max

-

Silicon (Si): 1.0% max

-

Phosphorus (P): 0.045% max

-

Sulfur (S): 0.03% max

-

Iron (Fe): Balance

This composition enhances corrosion resistance, especially against chlorides, acids, and alkaline solutions.

Key Properties of SS 316 Square Bars

-

High Corrosion Resistance

-

With molybdenum, SS 316 offers superior protection in marine and chloride environments.

-

-

Excellent Strength

-

It maintains strength at both cryogenic and elevated temperatures.

-

-

Non-Magnetic in Annealed State

-

Ideal for specialized applications where magnetism is a concern.

-

-

Heat Resistance

-

Performs well at temperatures up to 870°C in intermittent service and 925°C in continuous service.

-

-

Weldability and Formability

-

Easily fabricated, welded, and machined, making it versatile for manufacturing.

-

-

Smooth Surface Finish

-

Ensures a clean look for architectural and decorative purposes.

-

Manufacturing Process of SS 316 Square Bars

The production of SS 316 square bars involves multiple steps:

-

Melting and Casting – Raw materials are melted in an electric arc furnace and cast into billets.

-

Hot Rolling – Billets are heated and rolled into square shapes of desired dimensions.

-

Annealing – Heat treatment ensures toughness and relieves internal stresses.

-

Pickling – Removal of oxide scales for a smooth surface finish.

-

Cold Drawing (if required) – Used for precision sizes and better surface quality.

-

Finishing – Final processes such as polishing and straightening prepare bars for use.

Advantages of SS 316 Square Bars

-

Long service life in harsh conditions

-

High resistance to rust, scaling, and pitting

-

Hygienic and easy-to-clean surfaces

-

Excellent mechanical properties for load-bearing applications

-

Suitable for both structural and decorative purposes

-

Available in a wide range of sizes and finishes

Applications of SS 316 Square Bars

SS 316 square bars are versatile and used across various industries:

-

Marine Industry

-

Shipbuilding, boat fittings, propeller shafts, and offshore structures due to saltwater resistance.

-

-

Construction and Architecture

-

Structural frameworks, railings, decorative trims, and support beams.

-

-

Chemical Industry

-

Storage tanks, pipelines, and reactors handling corrosive chemicals.

-

-

Food and Beverage Industry

-

Equipment for processing, storage, and handling due to hygienic properties.

-

-

Pharmaceutical Industry

-

Machinery, medical devices, and cleanroom structures.

-

-

Oil and Gas Industry

-

Offshore drilling rigs, pipelines, and refineries.

-

-

Automotive and Aerospace

-

Engine components, fasteners, and structural reinforcements.

-

Sizes and Dimensions of SS 316 Square Bars

These bars are manufactured in various sizes:

-

Thickness/Side Length: 4 mm to 200 mm (custom sizes available)

-

Length: 1 meter to 6 meters (or as per requirement)

-

Finish Options: Bright, black, polished, hot-rolled, or cold-drawn

Manufacturers can also provide customized sizes depending on project needs.

SS 316 vs SS 304 Square Bars

| Feature | SS 304 | SS 316 |

|---|---|---|

| Molybdenum Content | Absent | 2–3% present |

| Corrosion Resistance | Good | Excellent, especially in chlorides |

| Cost | Lower | Higher |

| Applications | General-purpose | Marine, chemical, and medical |

Thus, SS 316 square bars are preferred where corrosion resistance is a top priority.

Maintenance Tips for SS 316 Square Bars

Even though stainless steel is durable, proper care extends its life:

-

Clean regularly with mild soap and water.

-

Avoid contact with harsh chemicals and chlorides.

-

Use non-abrasive cloths to maintain a polished finish.

-

Inspect periodically in marine or chemical environments.

Why Choose SS 316 Square Bars?

-

Ideal for demanding environments with saltwater and corrosive chemicals.

-

Suitable for both industrial strength and decorative elegance.

-

Backed by excellent machinability and weldability.

-

Offers long-term cost savings by reducing maintenance and replacement needs.

Conclusion

SS 316 Square Bars are a perfect blend of strength, durability, and corrosion resistance. They are widely used in industries that demand reliability in tough conditions, including marine, chemical, food processing, and construction sectors. With their superior performance and adaptability, SS 316 square bars stand as a reliable material choice for modern engineering and architectural applications.