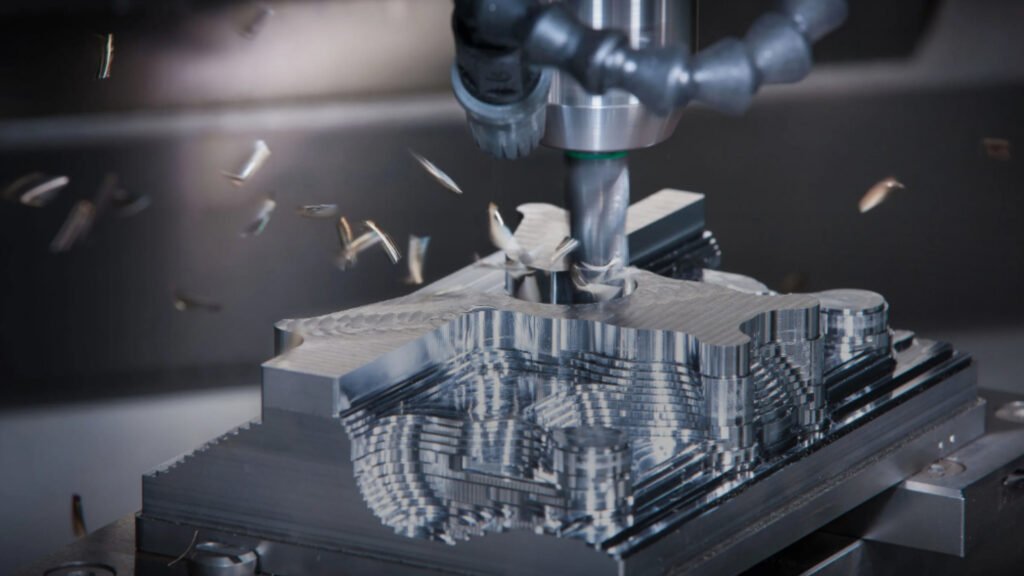

Manufacturing is evolving faster than ever, with businesses seeking ways to cut costs, speed up production, and maintain strict quality standards. One of the most important technologies driving this change is CNC Machining. By combining advanced computer programming with automated tools, CNC machining delivers consistent precision across a wide variety of industries. From aerospace engines to custom medical implants, its flexibility and reliability make it a game-changer for modern manufacturing. Understanding what CNC machining offers and how it benefits businesses can help companies stay competitive in an increasingly global market.

The Evolution of CNC Machining

From Manual Tools to Computerized Systems

For centuries, manufacturing relied on manual tools operated by skilled machinists. While effective, this method often produced inconsistencies and took significant time. CNC machining revolutionized the process by allowing computers to control machinery. With detailed programming, complex designs could be produced with accuracy that manual work could not achieve.

The Impact of Automation on Production

The introduction of CNC machining meant industries could scale production like never before. Automation reduced errors, improved speed, and made it possible to replicate thousands of identical components without variation. This marked a turning point, especially for industries demanding exact specifications.

Core Benefits of CNC Machining

Precision and Repeatability

One of the standout qualities of CNC machining is its precision. With tolerances often measured in microns, it ensures components fit seamlessly into larger systems. This accuracy also brings consistency—whether a company produces one prototype or a thousand parts, each will match the original design.

Efficiency and Cost Control

While CNC machining requires investment, it pays off by reducing labor costs, minimizing waste, and shortening production times. Automated tools can run continuously, which increases efficiency and allows companies to meet tight deadlines. These benefits make CNC machining cost-effective for both large corporations and smaller manufacturers.

Applications of CNC Machining

Aerospace and Automotive Uses

The aerospace sector requires lightweight, durable, and precise parts for engines, turbines, and safety-critical systems. CNC machining delivers this reliability. Likewise, in the automotive industry, CNC technology is essential for manufacturing components such as brake systems, gears, and engine blocks, where safety and performance cannot be compromised.

Healthcare and Consumer Goods

CNC machining also plays a vital role in healthcare by producing implants, surgical instruments, and prosthetics tailored to patients. In consumer products, the technology creates durable and finely finished components for electronics, home appliances, and luxury goods. Its adaptability makes it indispensable across industries.

Why Partner with MYT Machining

A Reputation for Quality and Expertise

With many CNC providers available, choosing the right partner matters. MYT Machining has built its reputation by delivering high-quality results through advanced technology and skilled professionals. Their ability to provide tailored CNC solutions ensures that every client receives products that meet their unique needs.

Looking Ahead: The Future of CNC

The future of CNC machining is even more exciting, with advancements like artificial intelligence, robotics, and smart factory systems. Companies that embrace these innovations now will remain competitive in the years ahead. MYT Machining is already preparing for these changes, making it a partner businesses can trust for long-term success.

Conclusion

In today’s competitive environment, CNC Machining stands out as a cornerstone of modern manufacturing. Its unmatched precision, speed, and versatility make it essential for industries ranging from aerospace to healthcare. Companies that integrate this technology benefit from reduced costs, improved quality, and greater innovation. For any business looking to grow and succeed in the future, CNC machining is not just a helpful tool—it is a necessity. Those who invest today will secure a competitive advantage for tomorrow’s manufacturing landscape.